When UV-light is mentioned most people think of either sunbeds, counterfeit money detectors, insect traps or water purification. However, UV-light is all around us, not just occurring naturally from sunlight but also in high-tech industrial, commercial and public services, medical applications. Everywhere make UV-light our daily lives more comfortable, secure, healthier and fun!

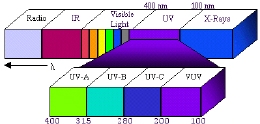

Ultraviolet light (UV) is that portion of the electromagnetic spectrum that lies between the purple part of the visible spectrum (400 nm) and emission of X-rays (100 nm). 1 nm = 1 millionth nm. The UV spectrum is normally divided into 3 different ranges: UVA, UVB and UVC.

UVA 400 nm-315nm:

Often referred to as 'blacklight' and is the longest wavelength region and with lowest energy. It represents the largest portion of natural UV light. The most common applications are different kinds of detection by means of fluorescent material: crack indication, leak detection, forensic investigation, hygiene and cleaning inspection. The UVA range causes also “sun tanning” since it makes the skin pigment (formed by UVB) dark.

UVB 315 nm-280nm:

Partially blocked by the ozone layer this is the most aggressive component of natural UV light and largely responsible for sunburn (erythema). UVB-light makes pigment forming start and epidermis thicker. UVB makes skin blush and can cause burn injury.

UVC 280 nm-100nm:

Generated from artificial light sources since it is totally absorbed by the earth's atmosphere. an important field of application is sterilzation of surgery instruments and drinking-water. The UVC-light is absorbed by DNA and thus can cause cancer and mutations. This is also the range that is most effective in inactivating bacteria and viruses.

Organic material, chemicals and many other substances are fluorescent and lights up with UV-light. Therfore can organic substances in dairy- and food industry light up in dark.

UV-light (UVA) can be used for effective monitoring of cleaning and hygiene in production equipment, production premises, toilettes, etc. The residues will glue in the dark, if no residues there is no fluorescences. With UV-light (UVA) staff can easily secure the hygienic standard before starting production. Instead of waiting for the answer from an ordinary analyse the production staff can get the answer directly.